Installation Methods for Steel Structure Gutters (Collector's Edition)

Common Types of Steel structure Gutters

a. Steel Plate Gutters

b. Galvanized Plate Gutters

c. Stainless Steel Gutters

d. Colored Plate Gutters

e. AluminumMagnesiumManganese Gutters

The installation methods for these gutters vary slightly. This article focuses on the installation methods for stainless steel gutters and colored plate gutters, hoping to help you solve some installation problems.

I. Installation Conditions for Steel Structure Gutters

1. The main steel beams and columns of the steel structure must be installed.

2. All highstrength bolts must be fully tightened.

3. For projects with parapet walls, the parapet columns and corresponding wall beams must be installed.

4. Steel plate gutters must be onsite.

5. Welding equipment and welders must be in place.

II. Installation Process for Steel Structure Gutters

1. Positioning the Gutter:

According to the design drawings, position the steel plate gutter using a crane or manual lifting. Temporarily fix the gutter with electric welding.

2. Aligning the Gutter:

After positioning the gutter, use a steel wire to align the outer edges of the gutter. Ensure the seams between the gutter sections are minimal and temporarily fix them with electric welding.

3. Welding the Gutter:

Use a 3.2mm welding rod to fully weld the bottom horizontal seams and the vertical seams on both sides. Ensure welding quality and control the welding current to prevent burning through the gutter.

4. Securing the Gutter:

Weld the bottom of the gutter to the top plate of the steel column to enhance overall stability. Temporarily fix any uncompleted sections as described or use steel wire ropes to tie the gutter to the wall beams or gutter brackets if conditions allow.

III. Opening Downspout Holes for Steel Structure Gutters

1. Positioning the Downspout:

Position the downspout holes as per the design, usually on the side of a steel column or beam. Avoid support positions to reduce the number of downspout fittings.

2. Opening the Holes:

Consider the installation method of the downspouts before opening the holes. Use gas cutting or an angle grinder, but never electric welding. After opening, trim the hole edges with an angle grinder, and weld the steel pipe downspout to the gutter, ensuring welding quality to prevent leaks.

3. PostWelding Adjustments:

Clean the welding slag and trim any raised welding metal to prevent water accumulation at the downspout. Use a hammer to slightly lower the downspout area to facilitate drainage.

IV. Painting the Steel Structure Gutters

1. RustProof Painting:

After completing the welding and passing the inspection, clean the welding slag and paint the welding areas with rustproof paint of the same specification as the original paint.

2. Surface Painting:

Apply the finish paint before installing the roofing panels. If not specified in the design, apply a coat of chloroprene rubber inside the steel plate gutter for corrosion protection.

A. Installation Steps for Stainless Steel Gutters

1. Preparation:

Follow the same conditions and downspout opening requirements as for steel plate gutters.

2. Welding:

Use argon arc welding with stainless steel welding rods of the same material and thickness as the gutter (typically 1mm). Conduct test welds before bulk welding, assign a dedicated welder, and ensure a helper for efficiency. Clean any contaminants from the welding rods before use.

3. Adjusting Gutter Fit:

Check the gutter for size discrepancies due to edge bending. Minimize gaps at joints, temporarily fix with tack welding, then weld the gutter bottom and sides. If possible, preassemble the gutter sections and number them for installation to reduce welding work and ensure quality. For large gaps, use scrap material for patches, ensuring thorough welding around the patches.

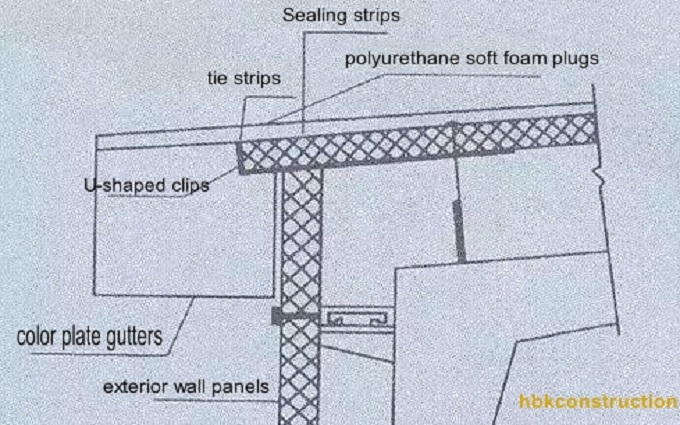

B. Installation Steps for Colored Plate Gutters

1. Timing of Installation:

Install after roofing panels are completed or simultaneously, based on site conditions.

2. Fixing the Gutter:

Fix the inner side of the gutter to the roofing panels using selftapping screws or rivets. Fix the outer side using gutter pull strips, connected to the roofing panels' peaks and purlins with selftapping screws.

3. Opening Downspout Holes:

Use a cutting machine to open the downspout holes as per design. Fix the downspout to the gutter bottom with rivets and seal the joints with neutral sealant.

4. Ensuring Flatness:

Ensure the flatness of the colored plate gutter matches that of the steel plate gutter. The quality of the main structure's installation is crucial for the gutter installation quality.

Notes

These summaries are based on site experiences and observations. Building structures often have unique characteristics, and construction plans should be tailored accordingly. Skilled and meticulous installation will enhance the decorative effect. Continuous experience accumulation and innovation are key to producing quality projects.

RELATED NEWS

- Efficient Canopy Structures: Enhancing Gas Station Functionality and Aesthetics 2024-07-05

- Gas Station Construction Budget: How Much Does It Cost to Build a Gas Station? 2024-07-04

- Eight Key Factors in Aluminum-Magnesium-Manganese Roof Design 2024-07-04

- What Are Roof Purlins? What Are the Principles of Roof Purlin Layout? 2024-07-03

- Characteristics of Hangar Tents 2024-07-03

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province