Key points in deepening the design of steel structure truss buildings

Truss structure is a common form in large public buildings, especially in projects such as stadiums, stations and airports. Its characteristics include large span and diverse shapes. Different types of truss structures include steel tube trusses, H-shaped Steel Trusses, box section trusses and angle steel trusses. Each type has specific considerations when developing the design.

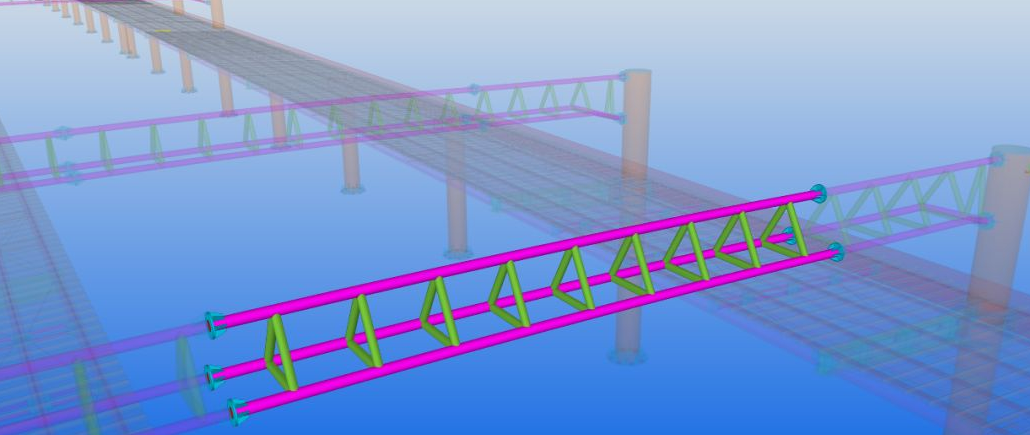

1. Steel tube truss:

- Ensure that the axis lines of the members are in a plane. When multiple members are connected in a node, the axis lines of the members converge at one point.

- The external dimensions of the main pipe shall not be smaller than the external dimensions of the branch pipe, and the weld must be continuous and smoothly transitioned throughout the circumference.

- When multiple pipes intersect, pay attention to the order of intersection to ensure continuous welding throughout the entire circumference.

- When making segments, the segmentation points of the upper and lower chords need to be staggered, and at the same time, avoid setting up butt linings to hinder installation.

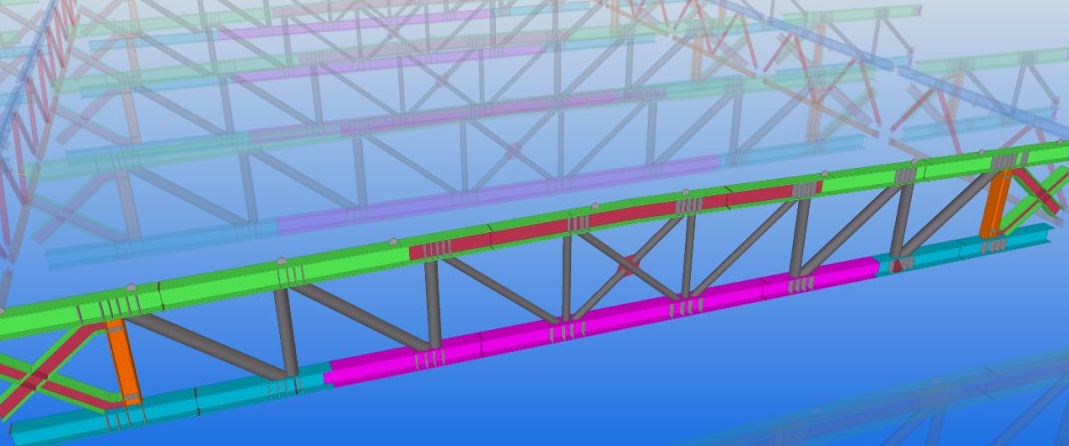

2. H-shaped steel truss:

- Emphasize the welding requirements of the upper and lower chords and avoid butt welding at the same position.

- If variable sections are required, avoid setting them at nodes to reduce butt welds.

- Control the overall size and use overall layout during processing to avoid on-site errors.

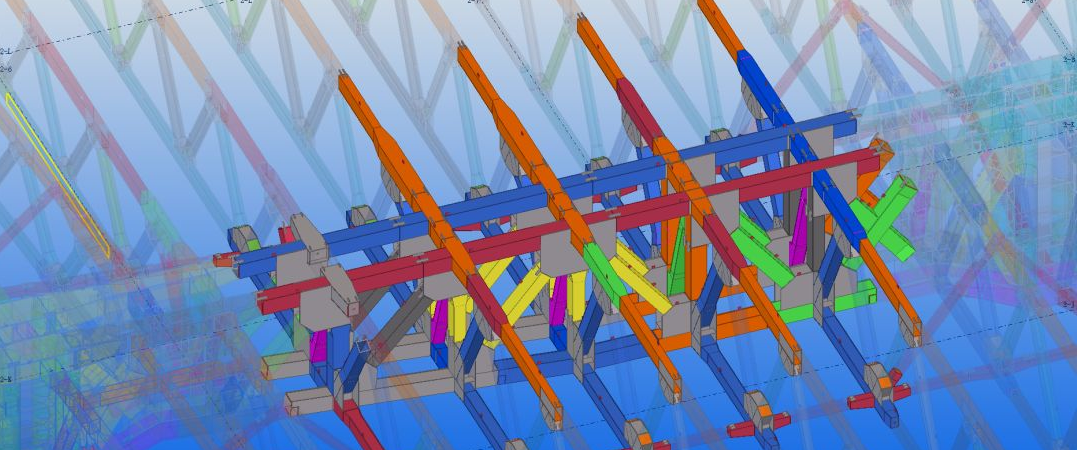

3. Box section truss:

- The quality of butt welds must be ensured, and the node form should be conducive to on-site welding.

- When connecting the box wall panels, the assembly of the stiffening plates must be considered to ensure that the stiffening plates that cannot be electroslag welded can be assembled to achieve 4-sided surround welding.

- During on-site connection, corbels are often used to set up corbels at node locations to simplify welds and ensure quality.

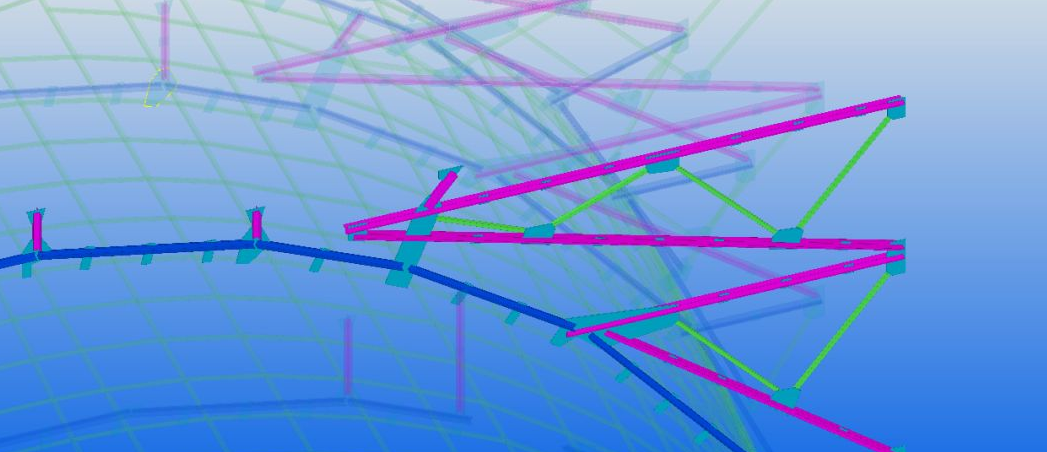

4. Angle steel truss:

- Ensure that the center line of the connecting bolt is as close as possible to the centroid line of the rod and that the axes at the node intersect at one point to avoid eccentricity.

- When two different cross-section materials are used for the same chord, the variable section position should be avoided at the node and can be merged with the on-site butt joint position to reduce butt welds.

In the in-depth design, in addition to paying attention to the truss structure system, the design of the roof and wall enclosure system is also one of the important contents. It needs to be completed together with the curtain wall unit, and the connection nodes should be made in the factory as much as possible to reduce on-site welding. Steel trusses have diverse shapes and complex structures, requiring flexible use of technology to meet project requirements. With the passage of time and the development of technology, the key points of deepening the design will be further enriched, providing more convenience for construction.

RELATED NEWS

- Efficient Canopy Structures: Enhancing Gas Station Functionality and Aesthetics 2024-07-05

- Gas Station Construction Budget: How Much Does It Cost to Build a Gas Station? 2024-07-04

- Eight Key Factors in Aluminum-Magnesium-Manganese Roof Design 2024-07-04

- What Are Roof Purlins? What Are the Principles of Roof Purlin Layout? 2024-07-03

- Characteristics of Hangar Tents 2024-07-03

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province