Steel space frame

Space frames are three dimensional, lightweight, rigid steel structures. It is constructed from interlocking struts in a geometric pattern.

Space frame

What is space frame?

In architecture and structural engineering, a space frame or space structure (3D truss) is a rigid, lightweight, truss-like structure constructed from interlocking struts in a geometric pattern.Space frames can be used to span large areas with few interior supports. Like the truss, a space frame is strong because of the inherent rigidity of the triangle, flexing loads (bending moments) are transmitted as tension and compression loads along the length of each strut.Space frames are three dimensional, lightweight, rigid Steel structures. It is constructed from interlocking struts in a geometric pattern.We use hollow steel tubes to undertake tension and compression which we connect using our own system nodes. Space frames can be used efficiently to cover huge areas with minimum interior supports。

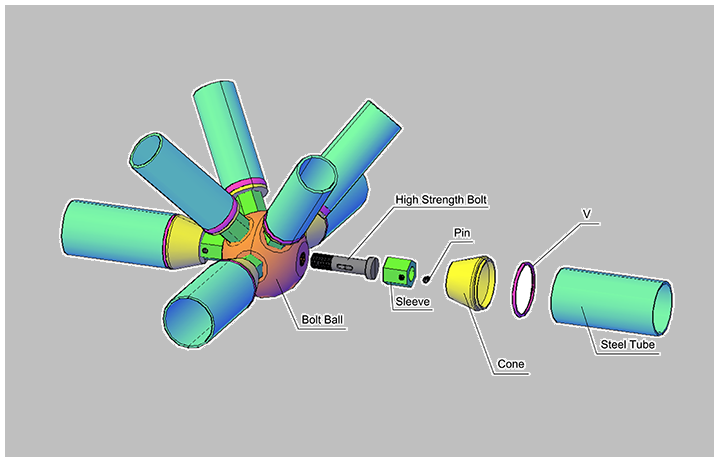

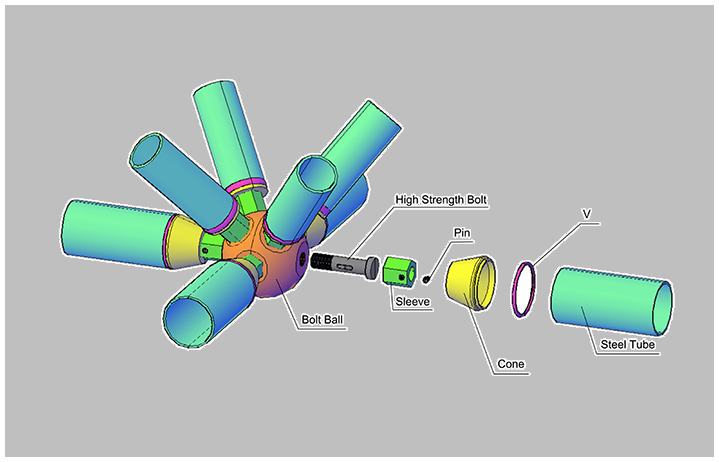

Space frame node

Space frame node

Nodes: In a space frame, nodes are forging steel balls drilled any number of holes according to the project needs to connect pipe members with bolts.

Pipes: Pipes are circular hollow section with cone-shaped steel forgings welded at the ends.

Bolts: Bolts can turn inside the conic elements to connect pipe member to the node and resist against the pulling forces occurring in the system.

Sleeves: The sleeves are special nuts without thread, a long hole on the lateral side to connect the bolts to the nodes.

Pins: The pins are the materials fixing the bolts to the sleeves,

so when sleeves turn, the bolts also turn. There is no any carrying function of the pins.

Advance structure system

Space frame system features a universal joint for easy erection that requires minimal equipment and skilled labor.

Cost Saving

Cost Saving

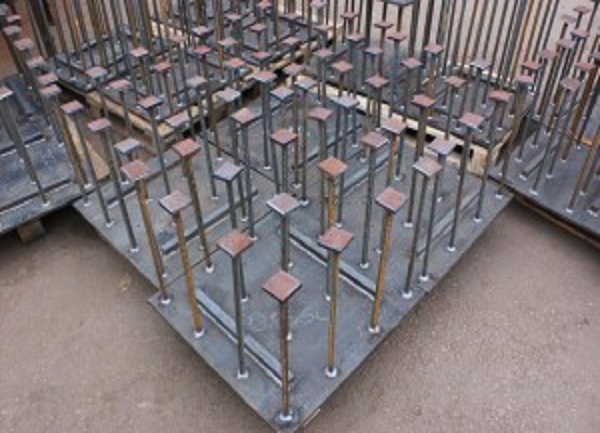

– Smaller foundations, cheaper substructures.– Very compact in transportation.– Re-usable, non-permanent structures

Up to 50% lighter

Smaller individual member sizes.– Member size optimization.– No heavy beams.– Achieves maximum span

Unparalleled Rigidity

3D load distribution.– Individual member sizing ensures ideal.– No torsion.– No bending.

Quick Assembly&Erection

Little or no site floor space is necessary.– No skilled labor required for assembly.– Simple bolt connection to node.– No welding on site.

INQUIRY

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province