Fiberglass Fabric - Reinforcing Buildings Worldwide

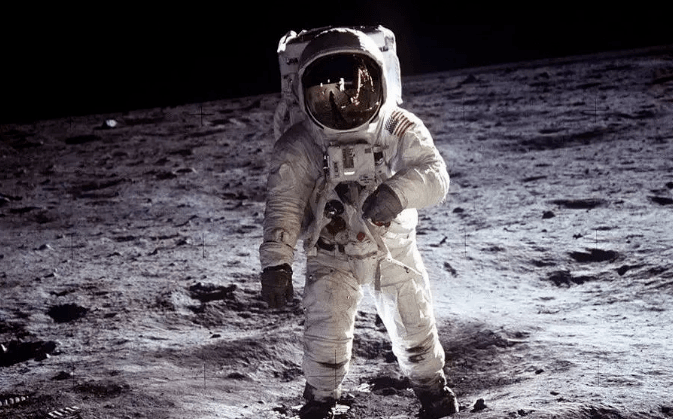

In 1967, during a test exercise, the Apollo 1 command module caught fire, resulting in the destruction of the module and the deaths of three astronauts. After this tragedy, NASA engineers redesigned the Apollo module and sought ways to improve the safety of nylon spacesuits. The spacesuits required an outer layer component that had to be durable, strong, lightweight, flexible, and flame-resistant. Owens Corning and DuPont collaborated to create a fabric known as "Beta cloth." This fabric's primary component was ultra-fine glass fibers spun into yarn, woven into fabric, and then coated with polytetrafluoroethylene (PTFE). This fabric was found to be non-flammable (with a melting point above 340 degrees Celsius) and durable enough to meet NASA's needs. The space agency applied this fabric to the outer protective layer of spacesuits used in the Apollo missions and Skylab program. This PTFE fiberglass fabric layer provided both thermal protection and shielding from lunar dust during moon landings. Although the spacesuits currently used on the space shuttle and International Space Station use Ortho-Fabric (a blend of GORE-TEX, Kevlar, and Nomex) instead of PTFE fiberglass fabric, this original innovation has now become a distinctive component in buildings.

In 1956, aerospace engineer Walter Bird founded Birdair Structures. In 1970, Birdair developed an air-supported vinyl-coated fiberglass fabric roof for the U.S. Pavilion at the Expo '70 in Osaka, Japan, guiding the company into exploring fiberglass fabric for architectural use. Birdair collaborated with Owens Corning, DuPont, and Chemical Fabrics Corporation to develop an improved, stronger PTFE fiberglass fabric, which has found widespread application in lightweight tensile membrane roof structures.

The same qualities that attracted NASA to fiberglass fabric also make it ideal for large permanent tensile membrane roofs. This material is stronger than steel, yet weighs less than 5 ounces per square foot. It provides up to 24% solar transmittance while offering up to 75% solar reflectance, meaning the fabric can absorb natural light while retaining heat, making it an energy-efficient roofing alternative.

Due to its durability and low-maintenance properties, it is also cost-effective. A properly maintained Birdair roof is estimated to last 30 to 35 years or longer, compared to traditional roofing materials like asphalt shingles or single-ply rubber, which last 20 to 25 years. As a non-flammable fabric, PTFE fiberglass is safer than many roofing materials and can create striking architectural forms.

In 1973, Birdair designed, manufactured, and installed the world's first permanent tensile membrane roofing system using PTFE fiberglass fabric for the athletics facility at La Verne University in California. Thirty-six years later, the original structure remains in good condition. Other iconic projects include the Jeppesen Terminal at Denver International Airport, the 105-acre Hajj Terminal in Saudi Arabia, Reliant Stadium in Houston (the NFL's first retractable roof stadium), the O2/Millennium Dome in London, UK (with a 22-acre fabric roof), and the Sony Center in Berlin, Germany. The company has manufactured and installed over 30 million square feet of PTFE fiberglass membrane across various projects.

RELATED NEWS

- Efficient Canopy Structures: Enhancing Gas Station Functionality and Aesthetics 2024-07-05

- Gas Station Construction Budget: How Much Does It Cost to Build a Gas Station? 2024-07-04

- Eight Key Factors in Aluminum-Magnesium-Manganese Roof Design 2024-07-04

- What Are Roof Purlins? What Are the Principles of Roof Purlin Layout? 2024-07-03

- Characteristics of Hangar Tents 2024-07-03

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province