How is the Shougang Ski Jump Both Sturdy and Light?

The Shougang Ski Jump once again captured the world's attention with Gu Ailing's spectacular leap. Located in the northern part of Beijing's Shougang Industrial Park, it is set against a backdrop of cooling towers, with a view of Shijingshan to the north, Qunming Lake to the east, and Yongding River to the west. Designed by the Architectural Design and Research Institute of Tsinghua University and constructed by Shougang Construction Group, this ski jump is reported to be the world's first permanently preserved ski jump, capable of hosting both snowboard big air and freestyle skiing aerials competitions.

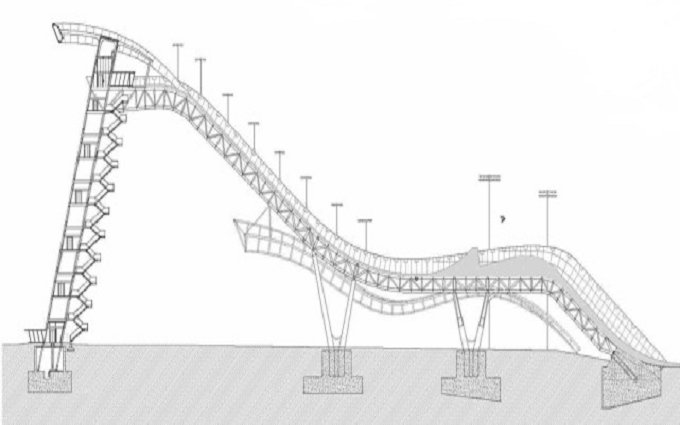

Distant View of the Ski Jump

Why do we say "once again" when introducing the ski jump? In fact, this ski jump is not new. It was completed in November 2019 and successfully hosted the 2019 FIS Snowboard and Freeski World Cup the following month, having already been tested by international competitions. From a distance, the smooth curves of the ski jump highlight its lightness. Lightness and sturdiness are two somewhat contradictory adjectives, but they are perfectly unified in this ski jump. How is this achieved?

FIS International Competitions

The Shougang Ski Jump features a Steel Truss structure, consisting of an upper ribbon tube truss, a lower ribbon tube truss, box girder columns, inclined box girder columns, variable cross-section V-shaped box columns, and track steel trusses. So, what is a truss structure? The most famous example is the Eiffel Tower in Paris, France, which is composed of slender steel components pieced together. The seemingly "chaotic" outer structure of the Bird's Nest stadium can also be considered a truss structure. Relatively speaking, truss structures are easier to construct and install, require less steel, and have a visually lighter effect.

Eiffel Tower

Mechanically, truss structures have a relatively simple force distribution. Typically, a single truss is considered a two-force member, distributing its own weight evenly to the two ends of the nodes or simply ignoring its own weight. In this case, the force on the truss itself is along the axial direction, making it very convenient to calculate the internal forces in each truss, which can be done by second-year students. Why can this be done? Because in the mechanical industry, the forces on such truss structures are generally large, and the effect of gravity can be ignored. However, for this ski jump, individual trusses are relatively long, and the effect of gravity cannot be ignored.

The main load on the entire ski jump, besides its own weight, comes from the thick snow covering the track. Snow, which looks light and fluffy when falling, becomes heavy when accumulated. News of structures collapsing under snow load in winter is not uncommon. For the competition, the total snow volume on the track is 7,920 cubic meters, about 4,752 tons, with an average thickness of 50 cm. These loads, along with the gravity of other auxiliary structures, are ultimately transferred to two box girder columns and two V-shaped box columns via the track's steel trusses.

Snow Load

Ordinary buildings rarely consider snow load, or simply convert it into uniformly distributed loads acting on the roof. Precise calculations of snow load are not very mature, which is one of the design challenges of the ski jump. Snow has a certain fluidity. The bottom layer, in contact with the steel plate, will slightly melt, reducing friction and possibly sliding down as a whole, causing an "avalanche." The ski jump uses a mesh structure to stabilize the snow, but slight movement still occurs. The surface snow has even greater fluidity, with athletes sliding down from high points, redistributing the surface snow, making it a dynamically changing load and complex to calculate.

With these loads and competition requirements, the design can begin. Overall, the ski jump is shaped like a "人" (human character), supporting each other, not only aesthetically pleasing but also conforming to mechanical principles. The left side bears the compressive force from the long right side. Inclined support can minimize the overturning moment caused by this compressive force, enhancing the mechanical properties of the inclined box girder column base. However, the elevator inside must ascend inclined, which must be an interesting experience.

Human Character Shape

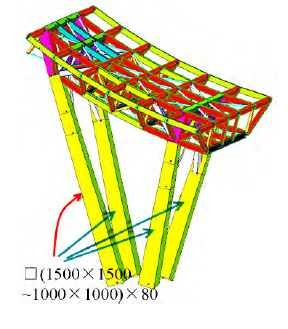

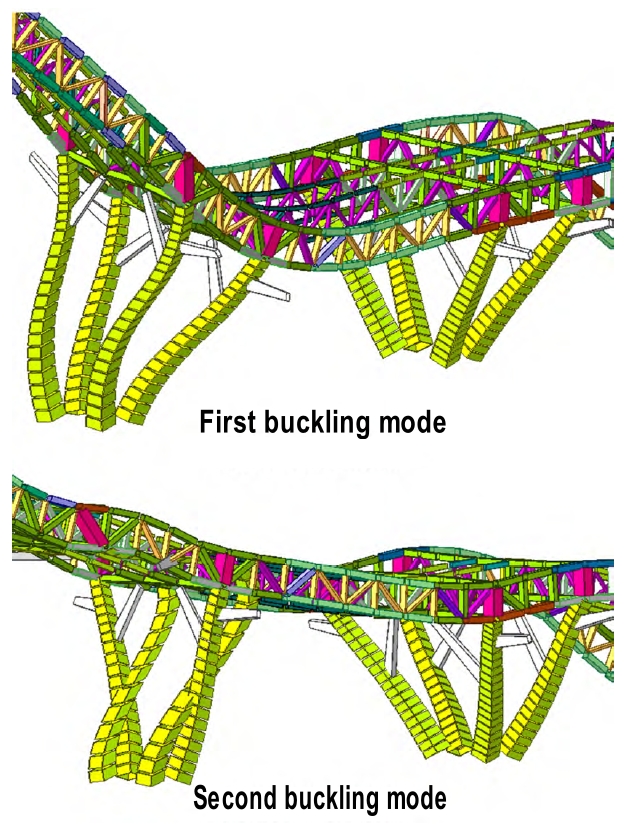

The total steel used for the ski jump is about 4,100 tons, roughly equal to the snow load, fully embodying the beauty of mechanics. The upper and lower ribbon trusses are circular cross-sections, hollow inside, significantly reducing the structure's self-weight. This is not cutting corners but a result of rigorous mechanical analysis, understood by students of material mechanics. Similarly, the hollow V-shaped box columns are designed with variable cross-sections, maximizing the mechanical performance of every inch of the structure without any waste. The main track trusses use box-shaped cross-sections for good shear resistance, preventing excessive displacement from crosswinds. The secondary trusses use H-shaped steel, focusing on bearing the snow load. Static analysis, modal analysis, and buckling stability analysis were conducted based on different load forms to complete the ski jump design.

Variable Cross-Section V Columns

Such a structure, neither more nor less, perfectly designed to meet strength, stiffness, stability, and vibration characteristics while minimizing structural self-weight. Combined with the upper and lower ribbons, the "flying" shape softens the rigidity of the Steel structure, making the ski jump light and graceful.

Buckling Mode Analysis

RELATED NEWS

- Efficient Canopy Structures: Enhancing Gas Station Functionality and Aesthetics 2024-07-05

- Gas Station Construction Budget: How Much Does It Cost to Build a Gas Station? 2024-07-04

- Eight Key Factors in Aluminum-Magnesium-Manganese Roof Design 2024-07-04

- What Are Roof Purlins? What Are the Principles of Roof Purlin Layout? 2024-07-03

- Characteristics of Hangar Tents 2024-07-03

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province