【Steel Structure·Technology】What is a staggered truss structure? If you need a large column-free space, come and learn about it!

Staggered trusses originated in the 1960s. This new structural system was developed by MIT under the sponsorship of the U.S. Steel Corporation. It is mainly suitable for multi-story building structures with rectangular or rectangular building planes.

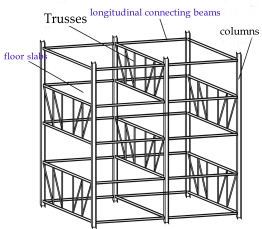

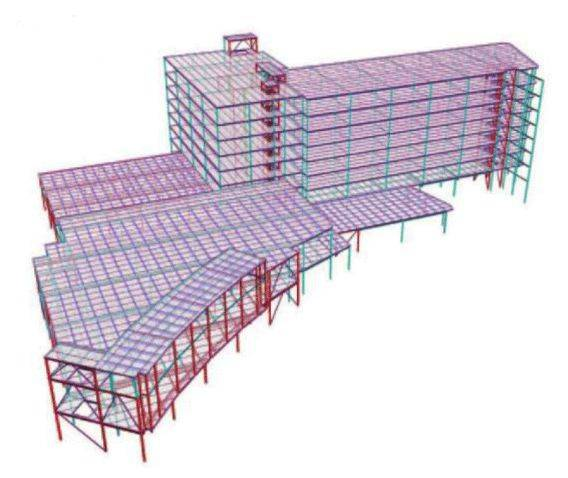

Composition of staggered trusses

The staggered truss structure is mainly composed of trusses, columns, floor slabs and longitudinal connecting beams. The structural columns are arranged around the house, and there are no columns in the middle; the height of the truss is the same as the floor height, and the length is the same as the width of the house; the two ends of the truss are supported on the outer columns, and the trusses are arranged along the longitudinal partitions of the house, and staggered up and down in adjacent column columns along the height of the house; one end of the floor slab is placed on the upper chord of the truss, and the other end is placed on the lower chord of the adjacent truss.

The staggered truss structure is mainly composed of trusses, columns, floor slabs and longitudinal connecting beams. The structural columns are arranged around the house, and there are no columns in the middle; the height of the truss is the same as the floor height, and the length is the same as the width of the house; the two ends of the truss are supported on the outer columns, and the trusses are arranged along the longitudinal partitions of the house, and staggered up and down in adjacent column columns along the height of the house; one end of the floor slab is placed on the upper chord of the truss, and the other end is placed on the lower chord of the adjacent truss.

Characteristics of staggered truss structure system

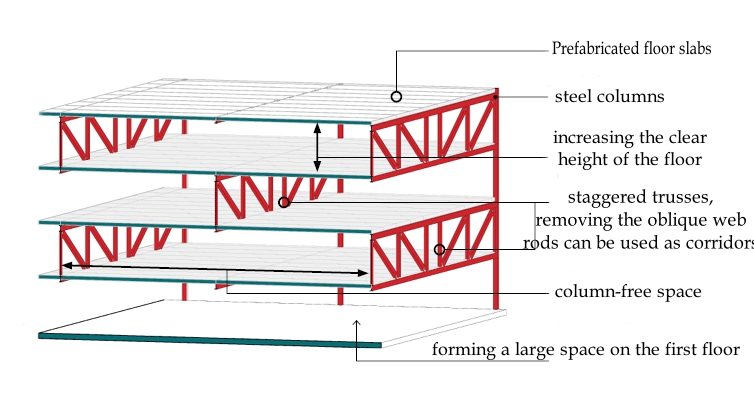

The staggered truss structure can form a large bay with twice the column spacing, and it is a column-free bay. In terms of architectural function, it can obtain a larger bay and depth, which is convenient for layout.

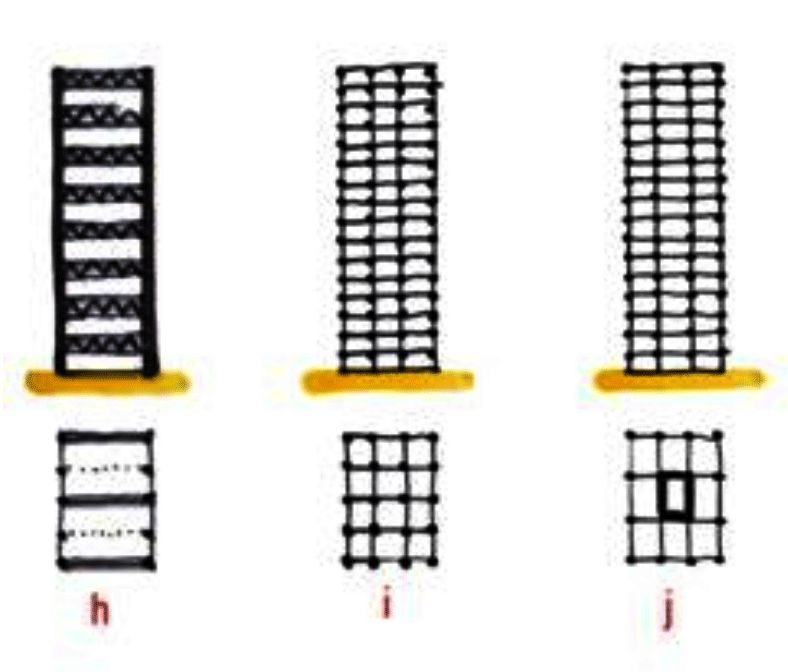

Comparison between staggered trusses and other structural systems

h) Staggered truss structure i) Frame structure j) Frame core tube structure

The structure of staggered trusses + prefabricated floor slabs can be installed without floor beams, thereby reducing the height of the structure and achieving a beautiful effect. If the diagonal web is not set in the mid-span interval of the truss, it can be set as a corridor or connected with adjacent rooms.

Most components of the staggered truss mainly bear axial forces, and steel can give full play to its high strength. Studies have shown that compared with multi-story residential buildings and hotels made of staggered trusses and steel frames, the amount of steel used is reduced by 50%.

From the perspective of construction, there is not much difference between the construction of staggered truss structures and ordinary trusses. Some trusses may be symmetrical with other trusses, and each layer of trusses may have only a slight difference; generally, they are made in the factory and assembled on site, which can be installed quickly and is not affected by weather, speeding up the construction.

Stress characteristics of staggered truss structures

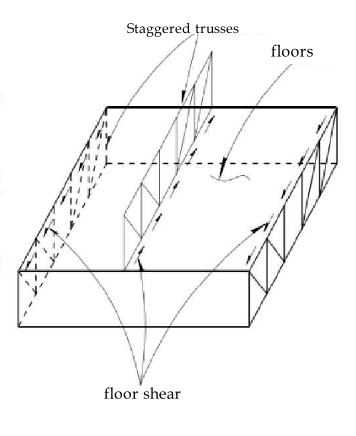

The staggered truss structure under lateral force is like the stress state of a cantilever beam. All columns are arranged around the structure, which is equivalent to the flange of the cantilever beam. The inter-column truss is equivalent to the web of the cantilever beam and has high lateral stiffness. The weak axis of the column can be located outside the truss plane, and the strong axis is located inside the truss plane. The longitudinal horizontal load is borne by the longitudinal structural system composed of columns, longitudinal connecting beams or supports.

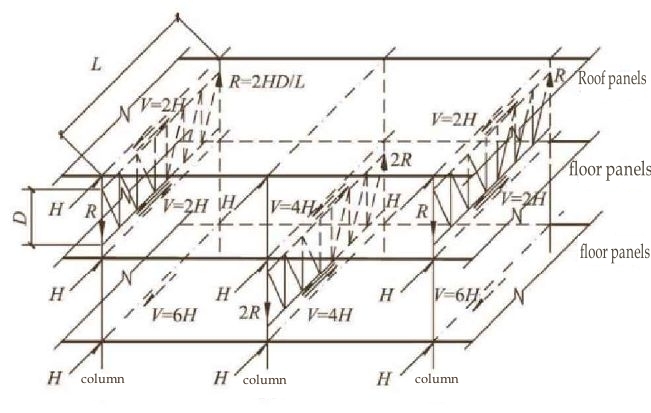

Horizontal force transmission of staggered trusses

Under the action of vertical load, the force is transmitted from the floor to the upper and lower chords of the supporting truss, and then to the outer columns. When the lateral load acts, the adjacent trusses are connected by a rigid floor. The shear force generated by the lateral horizontal load is transmitted to the upper chord of the truss through the connection between the floor and the truss chord, and then to the lower chord of the truss through the diagonal web, and then to the lower floor through the lower chord and its connection with the floor, and also transmitted to the column through the truss, and finally to the foundation layer by layer.

Staggered truss vertical force transmission

Engineering application

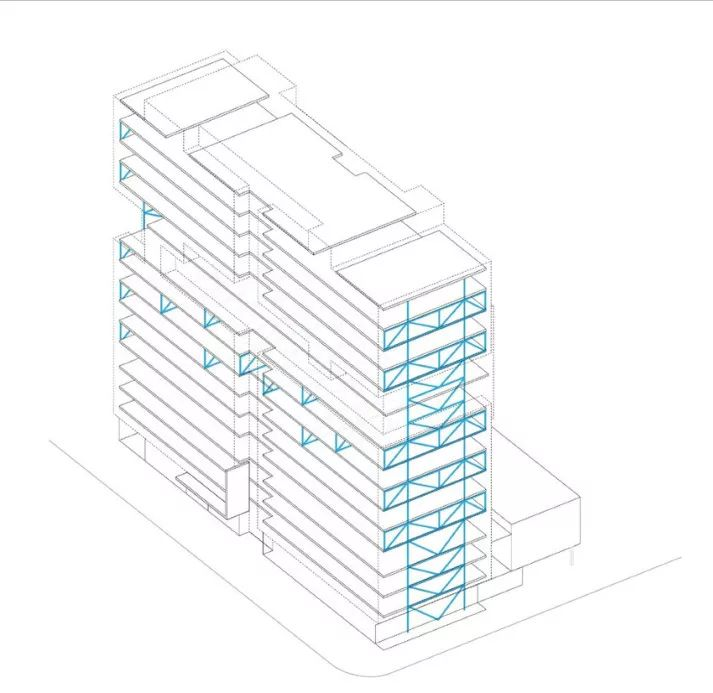

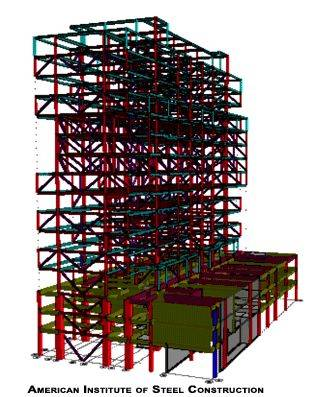

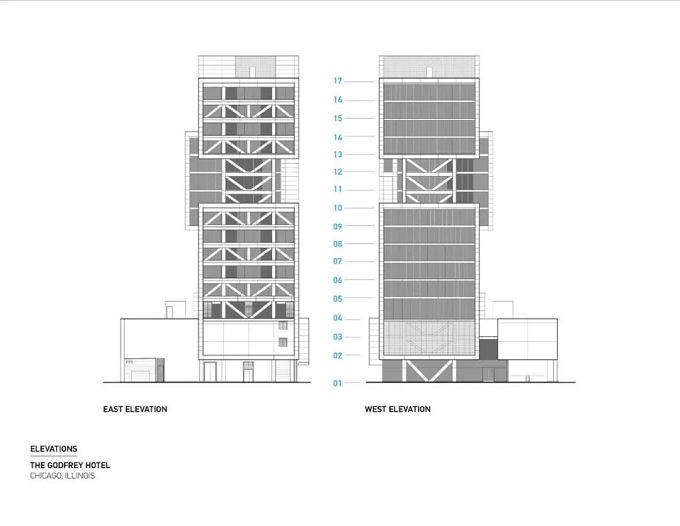

Godfrey Hotel in Chicago

The project uses staggered truss structure to build a large span space, with a total of 221 guest rooms, spa and fitness facilities. In addition, the designer cleverly uses the space to design a terrace on the fourth floor.

The hotel adopts a staggered truss structure system. Prestressed concrete slabs are arranged above and below the trusses, and there are trusses above. The use of the staggered truss structure system reduces the deadweight of the structure and shortens the installation time.

The staggered truss structure also meets the needs of large spaces on the lower floors of the hotel. Starting from the bottom of the building, the building moves forward and backward three times, creating spaces of different depths and 26 guest rooms of different forms.

Most staggered truss structures are simple squares, but the Godfrey Hotel cleverly combines trusses together to form a staggered truss structure, demonstrating the flexibility of the staggered truss structure and proving that not all staggered truss structures are square boxes.

Other staggered truss structure cases

Embassy Suite, New York

Marriot Courtyard, Edmonton

RELATED NEWS

- Efficient Canopy Structures: Enhancing Gas Station Functionality and Aesthetics 2024-07-05

- Gas Station Construction Budget: How Much Does It Cost to Build a Gas Station? 2024-07-04

- Eight Key Factors in Aluminum-Magnesium-Manganese Roof Design 2024-07-04

- What Are Roof Purlins? What Are the Principles of Roof Purlin Layout? 2024-07-03

- Characteristics of Hangar Tents 2024-07-03

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province