The Key Differences Between Four Roofing Materials - A Must-Read for Industry Insiders

Many people often ask, "Which type of roofing is best for Steel structures?" While your first thought might be a color steel roof due to its prevalence, the rising popularity of aluminum-magnesium-manganese roofs has led to questions about the differences between these materials. Many industrial facilities that previously used color steel are now regretting their choice.

For those not in the know, the plethora of roofing materials available can be overwhelming. Typically, people think there are only two or three common materials, but the differences between them are often unclear. This guide aims to shed some light on these materials, helping those with decision-making difficulties.

Before diving into roofing materials, let's first understand steel structures. A steel structure is a spatial framework made of rods arranged in a specific pattern, suitable for large-span buildings like stadiums, theaters, swimming pools, and factories. Regardless of the material chosen for the roof, factors such as aesthetics, practicality, lifespan, and cost must be considered.

Here are the five common materials used for steel structure roofs and their differences:

1.Single-Layer Color Steel Plate

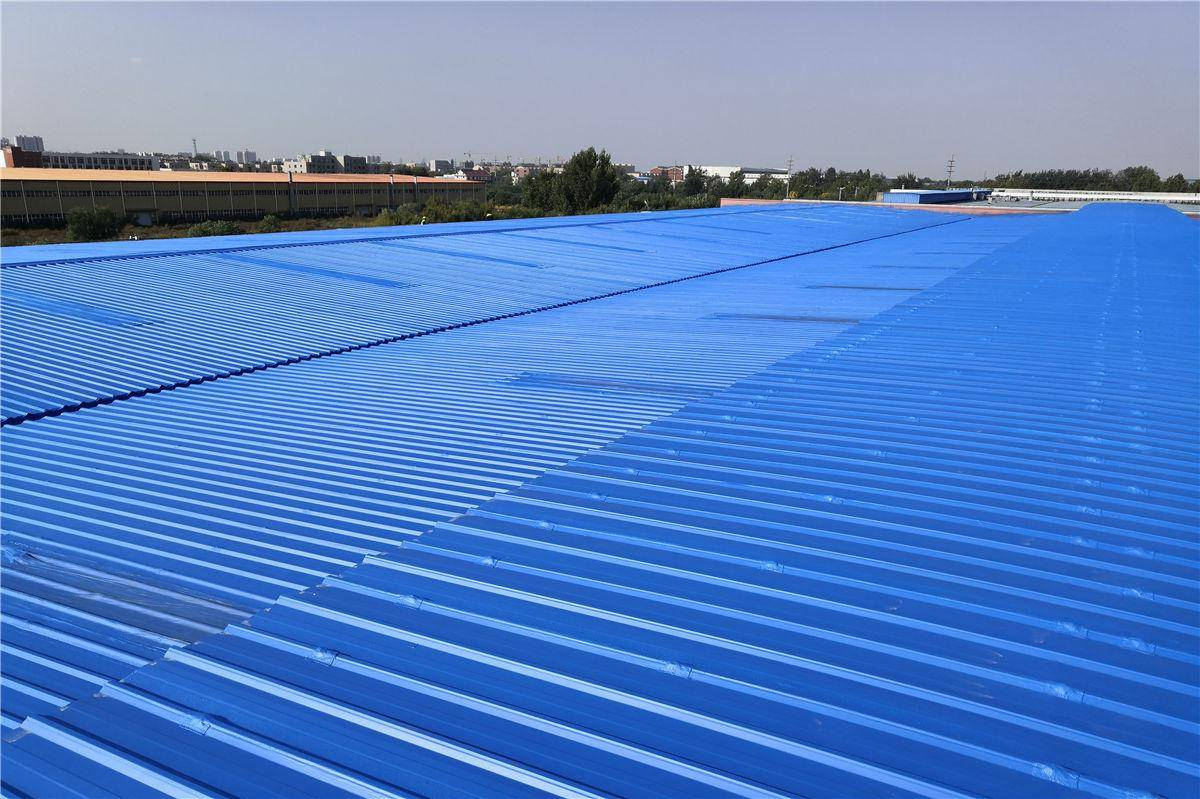

Single-layer color steel plates, aluminum plates, and aluminum-plastic plates are made by extruding profiled steel sheets, which have poor thermal insulation. Common thicknesses for color steel plates include 0.376mm, 0.4mm, 0.426mm, 0.476mm, 0.5mm, 0.6mm, and 0.8mm. Pricing is calculated per meter.

The difference between standard profiled color steel plates and corner-ridge type color steel plates lies in their wave height, with corner-ridge plates having higher waves and using corner-ridge brackets for fixed installation.

2.Roof Sandwich Panels (Composite Panels)

Sandwich panels consist of glass fiber insulation materials installed on-site, with the panels processed to length on-site for better insulation and easy transportation. Common setups include a bottom color steel plate, glass fiber insulation, and a top color steel plate. There are two types: exposed purlin and hidden purlin installation.

-Exposed Purlin: The bottom color steel plate is fixed to the upper flange of the C-shaped steel, with insulation material laid on top. This is the most common installation method.

-Hidden Purlin: The steel frame is hidden indoors and outdoors, requiring a bottom color steel plate under the roof purlin, followed by insulation material and the roof panel. This method requires scaffolding and has higher construction costs.

3.Sandwich Core Panels (Roof Panels)

Sandwich core panels are made from two layers of waterproof colored coated steel or other metal sheets with a core material in between. Common core materials include polyethylene, polyurethane, and rock wool. These panels have good insulation but are difficult to transport if too long. Rock wool core panels are fire-resistant, lightweight, have low thermal conductivity, good flexibility, and excellent sound insulation.

4.Aluminum-Magnesium-Manganese Roofs

These roofs are made primarily from aluminum, with notable advantages:

-Ductility: Aluminum is easy to process.

-Ease of Installation: Materials can be welded, glued, or riveted.

-Environmental Protection: Materials can be recycled.

-Lightweight: Aluminum's density is only a third of steel's.

-High Strength: Special treatment can enhance strength.

-Corrosion Resistance: Aluminum forms an oxide layer that prevents corrosion.

The typical thickness of aluminum-magnesium-manganese panels ranges from 0.7mm to 0.9mm. Simply put, these panels are superior to traditional color steel plates in many applications.

RELATED NEWS

- Efficient Canopy Structures: Enhancing Gas Station Functionality and Aesthetics 2024-07-05

- Gas Station Construction Budget: How Much Does It Cost to Build a Gas Station? 2024-07-04

- Eight Key Factors in Aluminum-Magnesium-Manganese Roof Design 2024-07-04

- What Are Roof Purlins? What Are the Principles of Roof Purlin Layout? 2024-07-03

- Characteristics of Hangar Tents 2024-07-03

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province