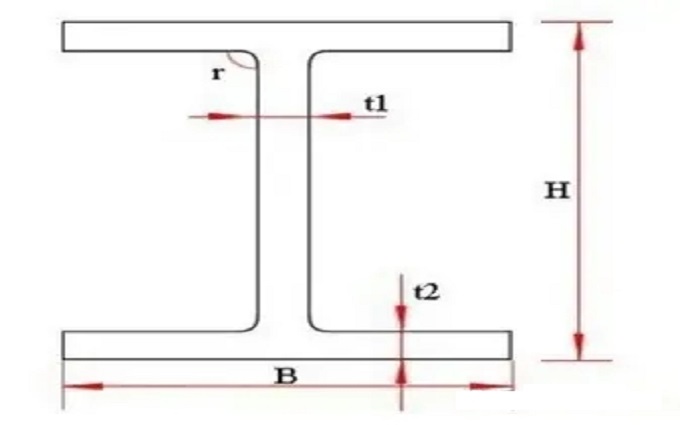

What does HW300*300*10*15 mean in steel structures?

In the Steel structure, HW300*300*10*15 represents: height H × width B × web thickness t1 × wing plate thickness t2, that is, the height H is 300mm, the width B is 300mm, the web thickness t1 is 10mm, and the wing plate thickness t2 is 15mm.

H-shaped steel is divided into two types: hot-rolled H-shaped steel and welded H-shaped steel (H). Hot-rolled H-shaped steel is further divided into wide-flange H-shaped steel (HW), medium-flange H-shaped steel (HM) and narrow-flange H-shaped steel (HN). Three types.

HW is an H-shaped steel whose height and flange width are basically equal; it is mainly used for steel core columns in reinforced concrete frame structure columns, also called stiff steel columns; it is mainly used for columns in steel structures.

HM is the ratio of H-shaped steel height to flange width, which is roughly 1.33~~1.75. Mainly used in steel structures: used as steel frame columns and frame beams in frame structures that bear dynamic loads; for example: equipment platforms

HN is an H-shaped steel whose height to flange width ratio is greater than or equal to 2, and is mainly used for beams; the use of I-shaped steel is equivalent to that of HN-shaped steel.

The main materials of H-shaped steel are Q235B, SM490, SS400, Q345, Q345B, etc.

Steel structures are vital components of modern construction, renowned for their strength, versatility, and efficiency. Comprising beams, columns, and trusses crafted from shaped steel and plates, these structures undergo rigorous rust-prevention treatments like galvanization. Welds, bolts, or rivets typically join components, facilitating swift assembly.

Notable for their high strength-to-weight ratio, steel structures excel in large-scale projects due to their resilience and ease of construction. Their uniformity and isotropic nature align with engineering mechanics, ensuring structural reliability. Mechanized manufacturing and installation streamline production, making steel structures the epitome of industrialization in construction.

Despite their resilience, steel structures are susceptible to corrosion, requiring periodic maintenance and protective measures. However, their minimal environmental impact, energy efficiency, and recyclability make them inherently sustainable.

Innovations like high-strength steel and specialized profiles like H-shaped or T-shaped steel cater to evolving architectural demands, enabling large-span and high-rise constructions. Additionally, advancements like light steel structures with thermal bridge solutions enhance energy efficiency and ease of construction.

In conclusion, steel structures embody the future of construction, offering unparalleled strength, sustainability, and adaptability to meet the demands of modern architecture.

RELATED NEWS

- HBK Construction Nigeria Plant Roof Truss Purlin Installation in Full Swing 2024-05-24

- HBK Construction Tension Membrane Structure Design for Gas Station Canopies 2024-05-21

- Construction process of steel structure factory building in Nigeria 2024-05-14

- Steel structure design effectively meets the requirements of work scenarios 2024-05-11

- Affordable Metal Workshop Building Kits 2024-04-26

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province