Detailed discussion on waterproof construction technology of steel structure metal roof

Preface

With the development of the times, large-scale Steel structure factories are blooming everywhere. Single steel structure buildings are being built more and more, and they are getting bigger and bigger. Steel structure roofs also come in various types, including standing seam metal roofs and spliced metal roofs. Roofing etc. At the same time, water leakage problems are gradually increasing with the service life of steel structure buildings, and the situation is likely to become worse and worse.

Common leaking areas

●Eaves, gutters

●Board seams and nail holes

●Lighting shed, fan opening and equipment hole

●Roof ridge

Analysis of causes of water leakage

1. Changes in thermal expansion and contraction of metal in steel structures

2. The steel structure metal is seriously aging

3. Steel structure metal rusts

Solutions

1. Meet the deformation needs of metal roofs. Choose waterproof materials with high tensile resistance and durability.

2. The selected waterproof material must have strong adhesion with the metal roof, which is the skin-type concept.

3. The covering not only has a waterproof effect, but also provides long-term corrosion-free protection to the metal roof surface.

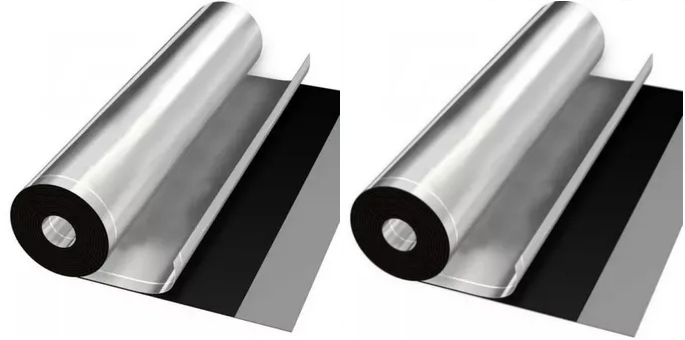

Special waterproof membrane for steel structure metal

【product description】

1. Coiled surface: Metal aluminum foil is used as the surface layer. Metal aluminum foil has the characteristics of moisture-proof, air-tight, heat insulation, resistance to solar ultraviolet rays, and corrosion resistance.

2. In the middle of the coiled material: the ultra-thin and strong tensile soft polyester cloth is added to enhance the tensile strength of the coiled material and solve the problem of the bridge edge construction of the coiled material.

3. Self-adhesive layer: Add aging-resistant butyl rubber to enhance the adhesive force. The ultra-thin structure can be applied to roofs with irregular color plates, and there is no need to worry about fires caused by hot-melt construction of rolled materials.

【Performance Features】

1. The construction is simple and cold. No professional construction is required. Just peel off the isolation film on the lower layer of the material and stick it in the right position. No gasoline primer is needed, and no need for too much edge pressing. It is economical and affordable.

2. It has strong adaptability to the thermal expansion and contraction of metal roofs. It can adhere to the roof according to the unevenness of the roof. It can firmly bond the rolled material to the color plate tiles, which is equivalent to thickening the thickness of the color plate, completely isolating the air from the metal roof, achieving both waterproof and anti-corrosion effects. The service life of the color plate roof is greatly extended.

3. Extra strong adhesion. Ordinary knife wounds and nail wounds can heal themselves at room temperature.

4. Good durability, artificial aging up to 25 years.

5. It has good tensile strength and is very convenient for repairing gaps in color plates.

【Product specifications】

Specifications: 1m wide, 20m long, 1.5mm/2.0mm

The surface can be painted or painted to change the color.

RELATED NEWS

- Understanding Primary and Secondary Members in Steel Structures 2024-07-05

- Is a Steel Villa Easily Destroyed? Let's Find Out 2024-06-12

- Do You Know the Differences Between Tube Trusses, Trusses, and space frame Stru 2024-05-30

- Advantages of Using Steel Structures for Coal Storage Sheds 2024-05-27

- The Ultimate Guide to Choosing the Right Gas Station Canopy 2024-05-27

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province