Strategies for Optimizing Costs in Steel Structure Construction

Steel structures are a popular choice in construction due to their durability and versatility. However, managing costs efficiently is essential for project success. Here, we'll explore the main components of steel structure costs and strategies for optimization.

1. Understanding Steel Structure Costs:

Material Costs: Steel material costs comprise a significant portion of the overall expense. Prices fluctuate due to market demand and raw material costs, typically ranging between 600-1000€ per ton.

Manufacturing and Processing Costs: These include expenses related to equipment, labor, and production. They usually account for 20-30% of the total cost.

Transportation and Installation Costs: Influenced by factors like distance and complexity, these costs typically make up 10-20% of the total.

Design and Construction Management Costs: Although relatively small (5-10%), they encompass fees for design, project management, etc.

2. Strategies for Cost Optimization:

2.1 Material Selection Optimization:

Carefully select steel specifications based on design and load-bearing requirements, considering factors like strength, corrosion resistance, and weldability.

Tailor material choices to structural design demands and environmental conditions, ensuring compatibility and cost-effectiveness.

2.2 Processing Cost Optimization:

Streamline processes to enhance efficiency and reduce labor and energy costs. Employ advanced CNC equipment and automation to boost accuracy and productivity.

Optimize design to minimize material usage, utilizing reasonable structural forms and cross-sectional shapes to reduce waste and improve utilization.

2.3 Transportation Cost Optimization:

Optimize component design to minimize weight and volume, reducing transportation expenses.

Design components for easy assembly and disassembly, facilitating transportation and reducing costs.

Choose transportation methods based on component size and weight, opting for the most economical option.

2.4 Design and Construction Cost Optimization:

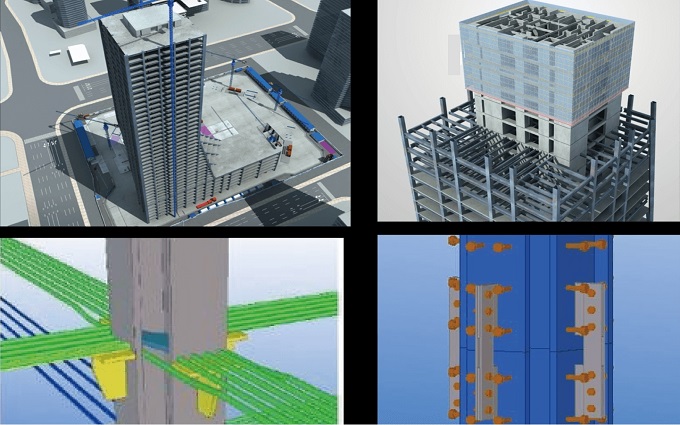

Leverage BIM technology for design optimization, reducing material usage through structural design refinement.

Strengthen construction site management to minimize material loss and waste, ensuring efficient use of resources.

3. Case Analysis:

Case Study: Steel Structure Factory Building Project in Yiwu

Structural design optimization reduced self-weight by 10%, while material selection optimization saved approximately 5%.

Automated processing and construction process optimization further reduced costs and improved efficiency.

Refined management practices minimized material loss, contributing to overall cost reduction of 15%.

Conclusion:

Cost optimization in steel structure projects requires a holistic strategy encompassing design refinement, material selection, efficient manufacturing, streamlined transportation, and meticulous project management. By leveraging advancements in technology and management practices, substantial cost savings can be achieved, enhancing project competitiveness and profitability while ensuring structural integrity and meeting project objectives.

RELATED NEWS

- HBK Construction Nigeria Plant Roof Truss Purlin Installation in Full Swing 2024-05-24

- HBK Construction Tension Membrane Structure Design for Gas Station Canopies 2024-05-21

- Construction process of steel structure factory building in Nigeria 2024-05-14

- Steel structure design effectively meets the requirements of work scenarios 2024-05-11

- Affordable Metal Workshop Building Kits 2024-04-26

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province