Mastering Steel Trusses: Design, Analysis, and Application Insights

Steel Trusses play a vital role in construction, offering structural support with a design consisting of upper chords, lower chords, and web members. Unlike regular beams, steel trusses have distinct stress patterns: the upper chords are subjected to compression forces, while the lower chords endure tension forces. This configuration forms a force couple that balances the bending moment generated by external loads. Additionally, the vertical component of the axial force in oblique web members acts to counterbalance shear forces. Each rod unit within the truss operates solely in axial tension or compression, allowing for optimal utilization of material strength. However, in practical applications, deviations from ideal conditions—such as non-ideal hinges at nodes—can introduce minor bending moments and shear forces, which may impact the axial forces within the truss members.

Analyzing Stress in Steel Trusses:

Assumptions: The calculation of internal forces in steel trusses relies on specific assumptions. These include the alignment of rod axes within a single plane and the presence of hinged nodes. External loads are typically assumed to act concentratedly at truss nodes.

Calculation Methods: Stress analysis in steel trusses involves the application of balance theory to establish equilibrium equations at each node. The node method, well-suited for simple trusses, facilitates the determination of unknown internal forces without the need for complex simultaneous equations. However, for more intricate truss configurations, such as joint trusses or those with complex geometries, alternative methods like the section method or a combination thereof may be necessary for accurate analysis.

Internal Force Distribution: The primary internal forces within steel trusses are axial forces, which are distributed unevenly across the various members. Understanding the distribution of these internal forces is crucial for selecting appropriate truss configurations and ensuring structural integrity.

Designing Connections:

Connection Methods: Steel trusses employ various connection methods, including welding, ordinary bolt connections, high-strength bolt connections, or riveting. The selection of a suitable connection method depends on factors such as engineering requirements, construction conditions, and the specific characteristics of the truss structure.

Appearance versus Internal Force:

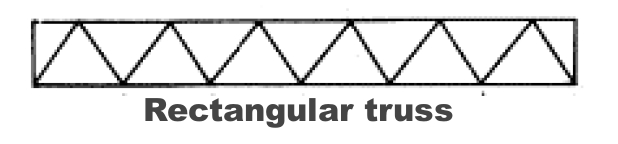

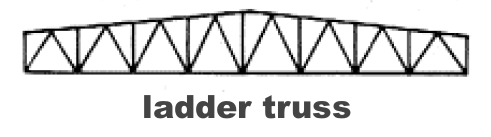

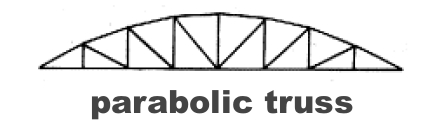

The shape of a steel truss significantly influences the distribution of internal forces within the structure. Different truss configurations, such as triangular, rectangular, trapezoidal, and parabolic trusses, exhibit varying force patterns. These force patterns impact material efficiency, construction complexity, and overall structural integrity.

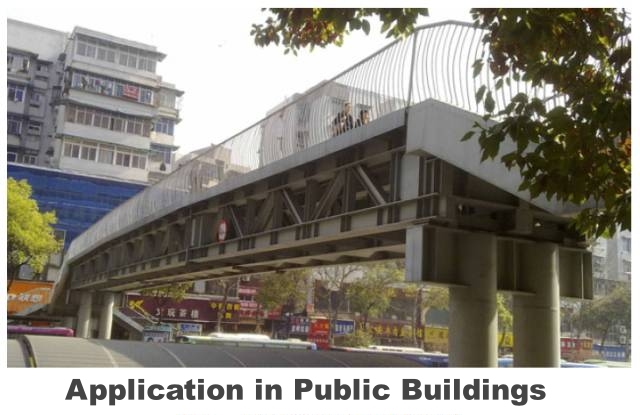

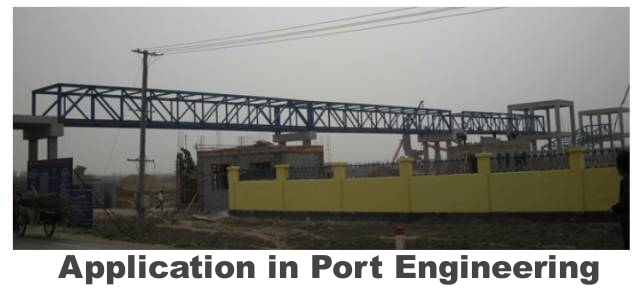

Application of Steel Trusses:

Steel trusses are widely utilized in diverse construction projects, including public buildings, industrial facilities, and infrastructure projects such as port cargo transportation trestles. Their inherent strength and stress characteristics make them suitable for supporting various types of loads and spanning long distances.

Conclusion:

When designing and selecting steel trusses, it is essential to consider a range of factors, including usage requirements, span length, load characteristics, material availability, and construction conditions. Attention should be paid to aspects such as rod cross-section design, strength and stability checks, and the impact of truss shape on internal force distribution. By carefully considering these factors, engineers can optimize the performance and economy of steel truss structures to meet project objectives effectively.

RELATED NEWS

- HBK Construction Nigeria Plant Roof Truss Purlin Installation in Full Swing 2024-05-24

- HBK Construction Tension Membrane Structure Design for Gas Station Canopies 2024-05-21

- Construction process of steel structure factory building in Nigeria 2024-05-14

- Steel structure design effectively meets the requirements of work scenarios 2024-05-11

- Affordable Metal Workshop Building Kits 2024-04-26

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province