Optimizing Steel Structure Factory Buildings: Design and Advantages Unveiled

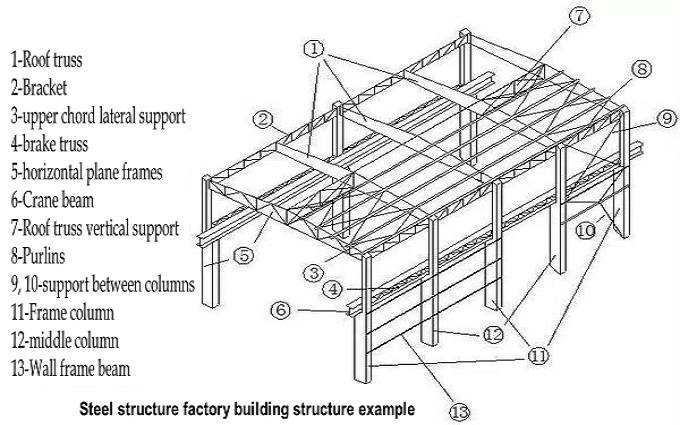

The construction of Steel structure factory buildings is mainly divided into the following parts:

1. Embedded parts (can stabilize the factory structure)

2. Pillars, usually H-shaped steel

3. Beams are generally made of H-shaped steel.

4. Purlins.

5. Support and braces.

6. There are two types of tiles. The first is a single-piece plate (color steel plate). The second type is composite board.

The main advantages of steel structure factory buildings are:

1. Light weight, high strength and large span: Although the density of steel is higher than other building materials, its strength is very high. Under the same stress, the steel structure has a small self-weight and can be made into a structure with a larger span.

2. Short construction period: The frame components of the factory building are mainly prefabricated in the factory and installed after being transported to the site. The assembly work is convenient for construction.

3. High fire resistance: When the surface temperature of the steel is within 150°C, its strength changes very little. When the temperature exceeds 150°C, its strength decreases significantly. Generally, fire retardant coatings are applied to the surface of steel structures to form a protective film to increase the fire resistance of the components.

4. Anti-seepage and waterproofing: Rainwater infiltrates mainly through nodes or gaps. To achieve anti-seepage and waterproofing, it is necessary to use sealing washers at the screw mouth and then use hidden fixation, and use sealant or welding at the overlap of the plates. Strict waterproofing of abdominal distension at various node locations.

5. Sound insulation and thermal insulation: Fill the metal roof layer with sound insulation material (usually glass rool), or apply heat-insulating reflective paint on the metal tile surface.

6. Ventilation and cooling: For steel structure factories with taller structures and larger spans, it is best to install an exhaust fan with a large exhaust volume on the roof to exhaust air outdoors; this will create indoor negative pressure and push a large amount of fresh air into the workshop from around it , forming air convection.

7. Good lighting: Install lighting panels or lighting glass at specific locations on the roof. Considering the service life of the skylight and the coordination of the roof panels, the joints must be waterproofed.

RELATED NEWS

- Efficient Canopy Structures: Enhancing Gas Station Functionality and Aesthetics 2024-07-05

- Gas Station Construction Budget: How Much Does It Cost to Build a Gas Station? 2024-07-04

- Eight Key Factors in Aluminum-Magnesium-Manganese Roof Design 2024-07-04

- What Are Roof Purlins? What Are the Principles of Roof Purlin Layout? 2024-07-03

- Characteristics of Hangar Tents 2024-07-03

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province