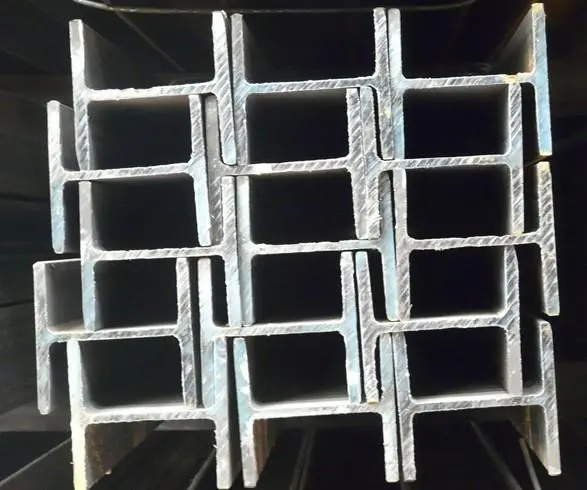

I-Beam and H-Beam

I-Beam: An I-beam features a cross-section resembling the letter "I," with wide horizontal flanges connected by a vertical web, offering a high strength-to-weight ratio for efficiently bearing heavy loads over long spans in construction projects.

H-Beam: An H-beam, shaped like the letter "H," consists of two horizontal flanges connected by a vertical web, providing robust structural support and strength, particularly suitable for heavy-load applications in construction and engineering.

The difference between H-beam steel and I-beam steel:

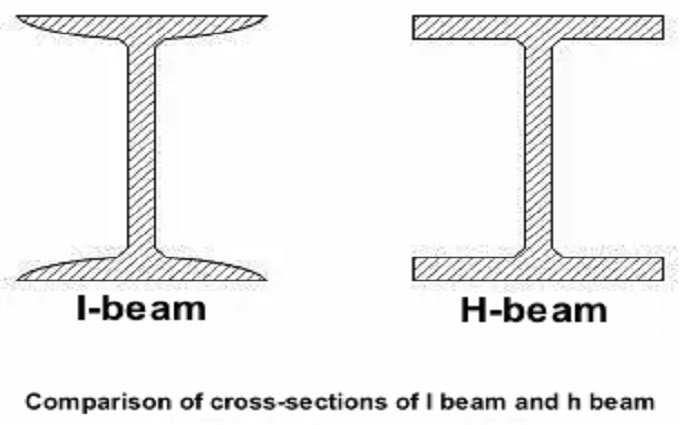

1. The I-beam has a small side length and a large height, and can only withstand force in one direction. The H-beam steel channel is deep and thick, and can withstand forces in both directions.

2. I-beams can only be used for beams, while H-beams can be used for load-bearing columns of structures.

3. The flange of H-beam steel is wider than that of I-beam steel, with greater lateral stiffness and stronger bending resistance. Under the same specifications, H-beam steel has a lighter weight than I-beam steel.

4. The flange of I-beam steel has a variable cross-section, which is thicker on the web and thinner on the outside; the flange of H-beam steel has a constant cross-section.

5. Whether I-beam steel is ordinary or light, due to the relatively high and narrow cross-sectional dimensions, the moment of inertia of the two main sleeves of the cross-section is quite different. Therefore, it can generally only be used directly on its web. Components subjected to in-plane bending or composed of lattice-type stress-bearing components. It is not suitable to use axial compression members or members that are perpendicular to the web plane and are curved, which greatly limits its application range.

6. H-beam steel is an efficient and economical cutting profile (others include cold-formed thin-walled steel, profiled steel plates, etc.). Due to their reasonable cross-sectional shape, they can make the steel more efficient and improve its cutting capacity. Different from the ordinary I-beam steel, the flange of the H-beam steel is widened, and the inner and outer surfaces are usually parallel, which makes it easy to connect with other components with high-strength bolts. Its size constitutes a reasonable series with complete models, which is convenient for design and selection. (Except I-beam steel for crane beams)

7. The flanges of H-beam steel are all of equal thickness, including rolled sections and combined sections composed of three welded plates. I-beams are all rolled sections. Due to poor production technology, the inner edge of the flange has a slope of 1:10. The rolling of H-beam steel is different from that of ordinary I-beam steel, which only uses one set of horizontal rollers. Because its flange is wide and has no slope (or the slope is very small), it is necessary to add a set of vertical rollers for rolling at the same time. Therefore, , its rolling process and equipment are more complex than ordinary rolling mills. The maximum height of rolled H-beam steel that can be produced in China is 800mm. If it exceeds the height, it can only be welded and combined.

RELATED NEWS

Categories

Latest News

Contact Us

Contact: Mr.Lu

Phone: +86-51668601029

E-mail: hbktech@163.com

Whatsapp:86+15152106218

Add: 1412, Building 2, Vanke Huaihai Xintiandi, Block 3, Quanshan District, Xuzhou City, Jiangsu Province